Dunlop Conveyor Belts. (Worldwide conveyor solutions) Dunlop Conveyor Belting has developed a wide variety of conveyor belts over the years to meet these demands in every stage of the production process. Giving a warranty of Two years over all our product range, proving the best quality in the market. All belts are manufactured in The Kingdom of Netherlands. Covering almost every conveying application from the lightest to the most severe service conditions.

Dunlop Product range

-

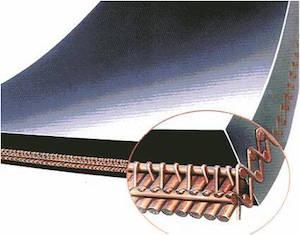

Multiply Belting

-

Steel reinforced belting

-

Profiled belting (Chevron)

-

Wear resistant sheeting

-

Dual direction positioners

-

Heat resistant (up to 400 deg.), oil and fat, high abrasion resistant and fire retardant covers exceeding DIN standards.

Arkeen Wear resistant Drum Lagging Rubber applications available in a range thickness and widths, with or without a diamond profile and in hardness’s of 600 shore A and 400 shore A, providing superior friction between pulley and belt preventing slippage, maximizing belt life and ensuring high endurance in the roughest working conditions, manufactured according to the German DIN standards and international ISO standards. Tech Trade can provide full lagging services for different pulley sizes and applications on site in a very short time.

Muller Beltex (FDA White Belts, Bucket elevators and PVC belts): FDA white belts are designed for use in the food processing industry. This belt quality has outstanding fat resistance and exceeds the required standards for products used in combination with dry foodstuffs according to the German DIN and USDA standards. Included in the range also Plastic conveyor belts, executed in PVC or polyurethane. Muller Beltex plastic conveyor belts are in accordance with DIN and ISO standards for diagonal, vertical and horizontal transport. Special belts for a variety of industries such as glass recycling, concrete processing, packaging machinery and the food processing industry are available from stock.

Gurtec (Rollers, Drums, Idlers): With more than 100 years of experience in the field, Gurtec focuses on developing and manufacturing top quality conveyor components. A wide range of rollers from standard belt conveyor rollers to shaft-free, rubber disk return, rubber impact and aluminum rollers. Complete frame and roller assembles painted or hot galvanized for belt widths from 350 to 3200+ mm. A wide range of light and medium duty standard pulleys as well as heavy duty pulleys. Primary Belt Cleaner suitable for light to heavy duty conveyors, thanks to the simple and reliable structure, easy to install on drive end.

Since 1981, DCL, Inc. has been the leader in manufacturing dry bulk loading equipment. DCL is recognized as the standard against which other loading systems are measured. DCL has met it as a designer, engineer and integrator, offering a complete one-stop source to develop, build and install bulk loading solutions. We’ve met it as an innovator, with ongoing research and development that has led to ground-breaking new ways to work.

"MLT Minet Lacing Technology was founded in 1947 with one aim: to manufacture conveyor belt fasteners, and quality lacing adapted to the needs, and easy to use. Minet Lacing Technology objective is, and will always be, that of its beginnings, and which established its success.”

With its 70 years of experience and know-how, MLT Minet Lacing Technology is the specialist of conveyor belts splicing solutions.

We manufacture in our factories :

- Mechanical fasteners

- Flexible PVC/PU lacings

- Super-Screw® flexible lacings

All kinds of vulcanizing tools

Dust Solutions Incorporated (DSI) manufactures Dust Suppression Systems for a wide-array of industries including Power Generation, Mining, Mineral Processing, Aggregate, Pulp & Paper, Wood Products, Hazardous Waste, Marine and Bulk Handling. We also offer DustTamer Wind Fence Systems for a variety of applications.

The following types of dust suppression-dust control systems are offered:

Dry Fog Agglomerative Dust Suppression Systems:

Our technology uses a special type of air-atomizing nozzle that produces a very dry fog (water droplets 10 microns or smaller) to agglomerate and remove airborne dust particles (PM-10) from various material handling and processing operations. It is our primary product and our specialty. Engineering Specifications often refer to this type of technology using the following terms: agglomerative dust suppression, ads (in caps), dry fog system, sonic dry fog system, ultra-sonic fog, air atomizing water spray system.

Wind Fence and Wind Screen Systems:

Wind Fence Systems are often used in conjunction with fogging as a way to help control and contain dust around open dump points. They are also used as a stand-alone system to reduce wind velocities around stockpiles and stack out operations. Wind reductions of 75% or more can be realized with the use of this unique knitted polyester material. This also offers a significant savings over construction of storage buildings. We supply the windscreen fabric, standoff brackets, attachment hardware, installation supervision and basic fence design. We also work with other firms to provide Computer Modeling, Detailed Engineering and Installation.

A long relationship with heavy industry and mining, we manufacture a range of products that can withstand the harshest industrial applications. Ranging from conveyor belt repair systems, pulley lagging, general purpose rubber sheeting, tank lining and specialized adhesives.

Our expanding range of industrial application rubber for mining and industry covers: hot and cold conveyor splicing products, rubber to metal bonding, rubber sheeting and specialised adhesives and cements. We are dedicated to supplying the best quality materials for the application.

Product Range:

Cold rubber repair material and Hardener - CV2002

used for all rubber to metal, rubber to rubber. fabric to fabric bonds and cold belt repairs with patching material

Holt vulcanizing repair material - Black cement / Heating Solution

used to for hot vulcanizing rubber repairs

Metal Primer

used for excellant rubber to metal bonds

Cushing Gum (uncured rubber sheeting)

used for endless splicings and hot repairs of rubber fabric belts

Plastocement and Hardener

used for cold splicing of PVC belts, plyurethance and PVC sheetings, PVC sheeting can be bonded to metal

Cleaning Solution (Tricoloroeythiline)

used for cleaning, freshening rubber before applying repair strips

Rubber repair strip (7, 15, 22)mm / 10m long - W(Reinforced)/without Ply